What is the X-BAR?

The X-BAR is a direct replacement to the Kodak 6240 (aka 4" Kodak Versamark) and the Kodak DH90 (aka 9" Kodak Versamark) printing systems.

What is the Universal Controller?

The Universal Controller is a replacment to the Kodak 400 System Controller and the 410 System Controllers. Developed by KaoCollins, this controller will print IJPDS and PDF data streams. It can print to the X-BAR 4" and 9" heads, Kodak 6240 printheads and possibly the DS9100 if there is a requirement.

Tell me more about the X-BAR high speed digital printhead?

With a DPI of 1200 x 600.

Currently a top speed of 1000 f/min, however tests have seen this print upto 1750 f/min.

What substrates can I print on?

Matched with the right ink, the X-BAR delivers high-quality results on porous bond, high-gloss coated stock, films, foils, and more.

How can I upgrade from my old inkjet system?

The X-BAR print module is designed to retrofit in place of the Kodak 6240 and Kodak DH90 9" printing system. Phoenix Digital Solutions Limited, (based in the UK but will travel worldwide) can install the new hardware on your existing systems. We will provide all related training and services to get you printing as well as the right ink for your substrate, which is provided by KaoCollins.

What can I expect for printhead downtime?

You can be back up and running in 2 to 10 minutes. Another plus, the module can be set in an idle mode without the need to shut down the entire machine, which significantly reduces downtime during startup. No more Charge Shorts, lengthy Shutdown's and Ready sequences to deal with.

What is the expected lifetime of an X-BAR print module?

At least 10,000 - 20,000 hours per XBAR module. Both the 4" print width XBAR head and 9" print width XBAR head contain 6 x SAMBA modules (manufactured by Fujifilm).

How many colours can the X-BAR run?

The X-BAR is a monochrome system. Each X-BAR head can run black or spot-color inks. Contact us for more information.

What is the droplet size of the X-BAR Samba modules?

6 pico-liters but can vary with the different waveforms that are available.

What inks can I use in the X-BAR Printhead?

Kao Collins is always developing new inks. Right now, compatible industrial inkjet inks include water-based dye, water-based pigment, pigment polymer, and the versatile UV-curable. Also, the electron beam (EB) curable ink is designed for the X-BAR.

What is the ink consumption of the X-BAR?

You can expect up to a 50% reduction in ink usage.

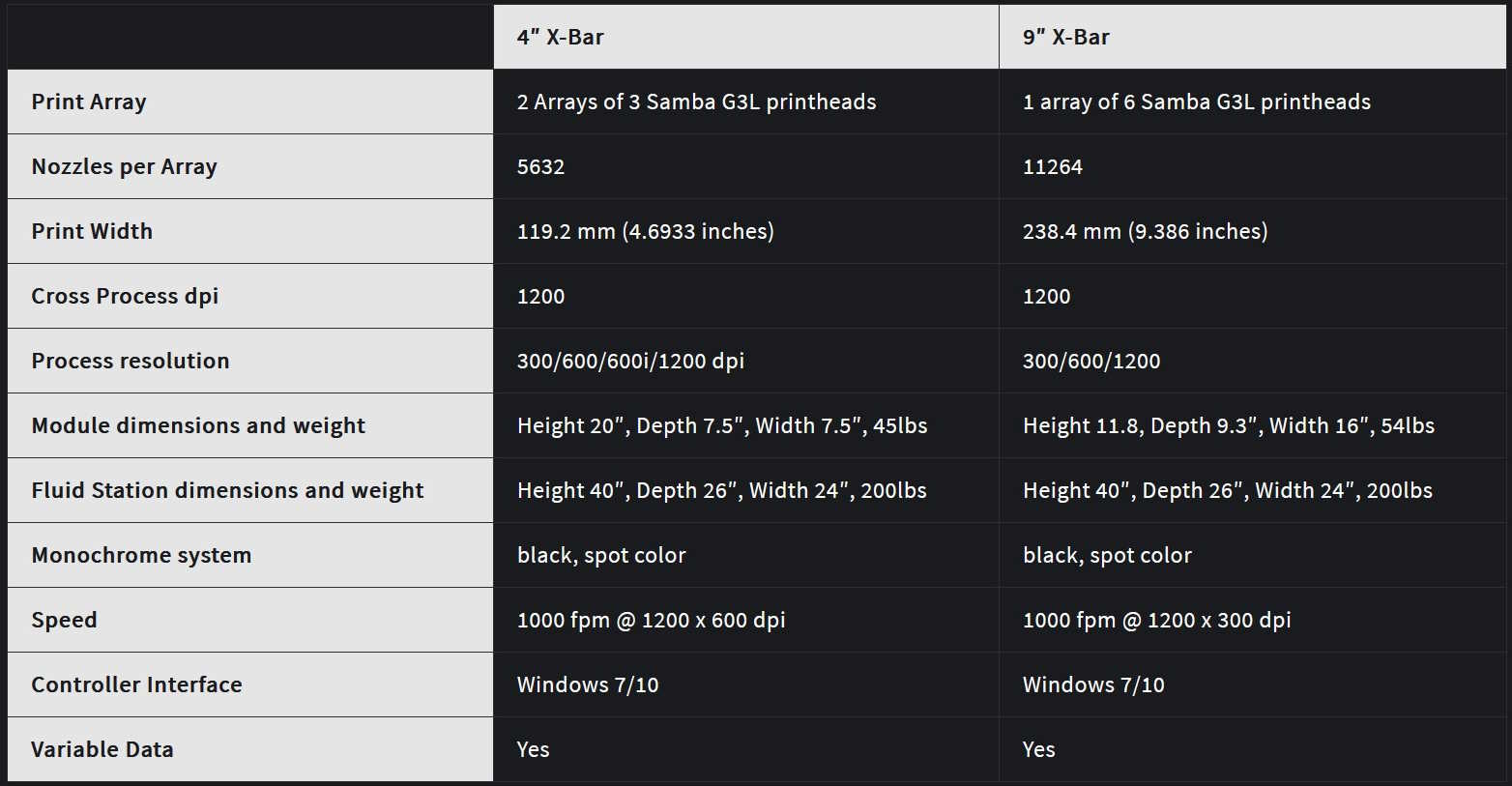

How many nozzles are int he X-BAR heads?

4-inch module has 2 arrays of 3 Samba G3L printheads. Each array has 5,632 nozzles.

9-inch module has 1 array of 6 Samba G3L printheads for a total of 11,264 nozzles.

What is a SAMBA Print module?

SAMBA is an extensible “printhead on a chip” technology that is analogous to the evolution of the Integrated Circuit (IC) from a single chip with limited functionality to Large Scale Integration (LSI) incorporating thousands of integrated functions. This breakthrough in industrial inkjet printhead design results in the potential of having the packing density and cost of Thermal Ink Jet (TIJ), coupled with the high throughput of Continuous Ink Jet (CIJ) yet providing the operational flexibility associated with Piezo Ink Jet (PIJ). Developed by FujiFilm.

What is MEMS Technology?

Silicon Micro-Electro-Mechanical Systems (MEMS) are used in piezo printhead ‘channel’ plates, the channels from the ink manifold to the actuator chamber, and then to the nozzles. These ultra-small components are what make high-speed, high-resolution industrial inkjet printing possible.

What is the print resolution for the modules?

For both the 4-inch and 9-inch modules, the cross-process dpi is 1,200. The process resolution is 300, 600, or 1,200.

What is the print width of an X-BAR head?

The printing width of the 4-inch module is 4.6933 inches (119.2 mm)

The printing width of the 9-inch module is 9.386 inches (238.4 mm )

How can I mount the printheads to my existing transport?

We can help you build a custom printhead mount, we will remove your existing inkjet printhead mounting and build a new custom designed transport head, this will sit on top of your existing paper handling transport and support the printheads.